Print inspection

100% Quality Inspection

by means of camera system with unique software algorithms; 100% Sorting: weeding out of substandard products; 100% approved and documented quality.

Solution example 1:

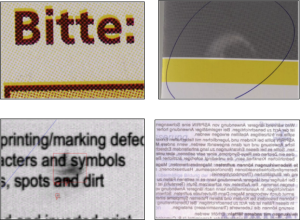

Detectable Defects:

- Print defects incl. position and register; colour; under/overinking

- Text as missing characters and missing accents

- Material imperfections; size

- Die cutting defects

- Hot foil stamping defects e.g. completeness

- Markings, scratches, damages, dirt

- etc.

Example Print defects:

Example Hot foil stamping defects:

System:

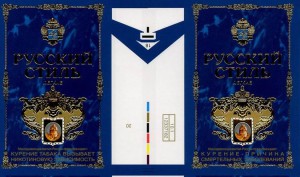

Solution Example 2:

Document inspection and sorting system – Quality control, sorting and packing of high security documents.

Features:

Quality Control

- Complete front- and backside verification

- UV- and IR verification

- OCR- and barcode verification

- Logo and emblem recognition

Grouping/sorting

- Selective grouping of paper stacks

- Grouping by numbers or selectively by database connection

Packaging

- Various packaging possibilities

- Banding and cross-banding

- Inserting in enevelopes

- Packaging in boxes

Printing of delivery notes, packaging lists and transport labels

Optional: label attachment, hot stamping unit, ink-jet printing