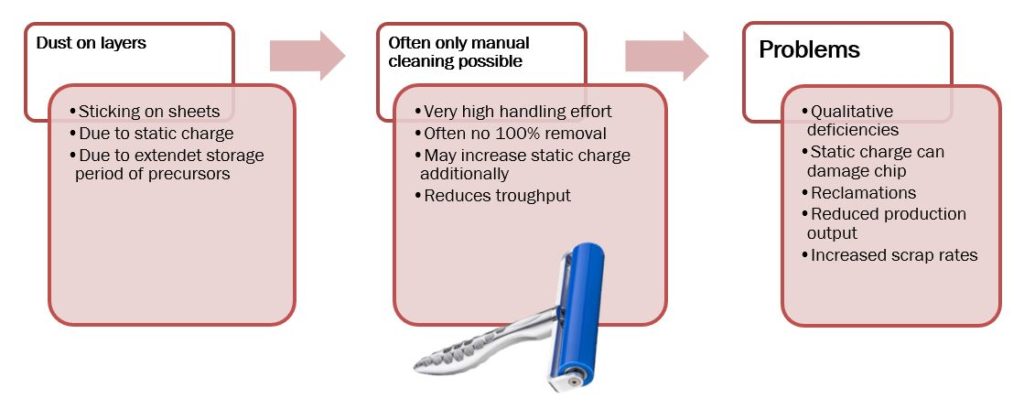

A frequent challenge for sheet- based card production is dust and impurities, which stick to the electrostatically charged sheets. Cleaning is therefore a necessity before the individual card layers can be gathered for lamination. This step usually involves increased personnel handling and time expenditure, harbours quality risks and can drive up reject rates, which ultimately affects throughput.

Our ABIS – ASC automatic sheet cleaning system provides effective remedy for this. It reduces manual handling by automatically cleaning both sides of the sheet in one pass, ensuring process reliability, and increasing production throughput. This way the individual layers can be cleaned immediately before collation.

Increase your quality level by reliable, full-surface cleaning on both sides, low handling effort due to automatic working principle, reduced scrap rates and higher quality.

.

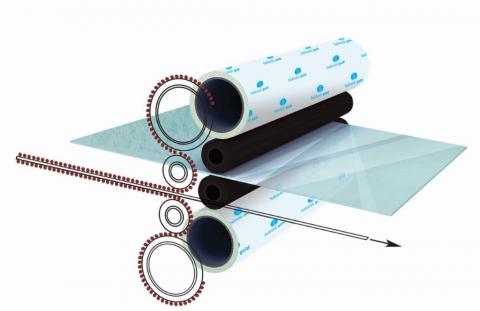

The system consists of a flat pile feeder that automatically separates the sheets using vacuum and blowing air to feed them to the cleaning unit. A double-sheet detection ensures error-free infeed and due to the separation from the underside, sheets can be added during operation.

.

The cleaning process itself is realized by elastomer rollers which are on top and on bottom of the sheets. They ensure reliable contact-based removal of dirt particles which are subsequently transfered to adhesive rolls. These rolls consist of several layers coated with acrylic adhesive, which absorb the dust and also provide the elastomer rolls with their adhesive properties. One adhesive roll consists of 60 layers, which can be easily peeled off after consumption to restore the function. After that, the adhesive roll is just replaced.

Two built-in anti-static air bars, that are located before and after the cleaning rollers, use ionized air to reduce the static charge on the sheets and decrease dust re-attraction. All elements of the cleaning unit can be drawn out of the machine for easy maintenance.

The on both sides cleaned sheet are subsequently transported to an inclined delivery table and gathered there. The various cleaned layers can then be collated and stitched for subsequent lamination.